You don't have to resign from the wooden charm to create interiors that meets the highest fire safety requirements.

GUSTAFS PANEL SYSTEM® fulfills high fire safety requirements regarding emergency routes, concert halls, theaters, hotels, airport terminals and other public buldings.

GUSTAFS PANEL SYSTEM® was tested for reaction to fire, in leading european research institutes in:

SWEDEN, POLAND, BELGIUM, DENMARK, FRANCE, GERMANY, NORWAY, SPAIN, GREAT BRITAIN, ITALY and was as well tested in USA, TAIWAN and RUSSIA.

In Poland Gustafs Panel System® (GPS) was tested in CNBOP in Józefow (certified by the Polish Center of Accreditation). The result of the research: GPS was classified regarding to the Polish classification as non-ignitable

In Sweden Gustafs Panel System® was tested in SP Technical Research Institute of Sweden, in one of the largest fire testing laboratories in Europe.

To proceed safe evacuation, the most important factor when a fire occurs is that the ceiling will not collapse. Gustafs Panel System® suspended ceiling was tested for reaction to fire according to the test method SS 02 48 22 (NT FIRE 003). The test simulates fire conditions: gasses and smoke. Within 10 minutes the temperature is raised from 20 up to 650 Celsius degrees.

After the tests, the ceiling panels and the bearing construction were still untouched as well as the material behind the panels.

As early as 1997 the European Commission decided that a common standard should be created which would harmonize the various fire testing procedures that existed throughout the European Union. Euroclass has now been adopted by the member countries and after a transitional period is now replacing existing nation testing certification.

In Poland, until the moment of complete introduction of the Euroclass system (predicted for the year 2011), both the current and Euroclass system will exist.

Gustafs panels were tested, according to the new methods required within the European Union, giving high results in class B

The research results confirmed that Gustafs panels parameters classify the product in the best of additional classes: s1 and d0, which means: Gustafs panels don’t create smoke and don’t create flaming particles or droplets when subjected to fire.

Gypsum wood board used to the Gustafs panels manufacturing process is classified as: A2-s1, d0, the veneered board is classified as B-s1, d0

GUSTAFS PANEL SYSTEM® IS CLASSIFIED ACCORDING TO EUROCLASS AS: B-s1, d0

IN POLAND CLASSIFIED AS: Non-ignitable

FIRE

Statistics prove that within the European Union every year approximately 5000 people get injured or die due to fire. Not only flames and temperature, but smoke and gasses are dangerous as well.

TO PROVIDE FIRE SAFETY CONDITIONS IN THE BUILDING IT IS BEST TO:

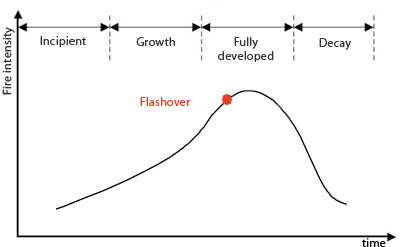

- Eliminate flashover or hold it back

- Prevent fire spread

Flashover (International Standards Organization - ISO) is the near simultaneous ignition of all combustible material in an enclosed area.

At the flashover point the temperature is about 600 degrees. The flames reaches the fire gases and an explosion takes place (the temperature goes up to 1000 degrees at once). Fire and smoke spreads in the rest of the building

To meet the high fire safety requirements it is necessary to provide building materials:

- CALSSIFIED IN THE APPROPRIATE FIRE CLASS

- DELIVERED FROM A RELIABLE PRODUCER

GUSTAFS PANEL SYSTEM®:

- HOLDS BACK THE FLASHOVER POINT

- GUARANTEES TIME AND CONDITIONS TO PROCEED SAFETY EVACUATION

- PROTECTS FROM BIG DAMAGES CAUSED BY FIRE

GUSTAFS PANEL SYSTEM® - B-s1,d0 ::

SBI (Single Burning Item): After a period of 5 minutes the board is still intact and protecting the base material behind the panel.

GUSTAFS PANEL SYSTEM® Provides high fire resistance and limits the fire spread

Fire Safety requirements

Thanks to the fire classification of building materials it is possible to choose an appropriate product that guarantees high fire safety.

As early as 1997 the European Commission decided that a common standard should be created which would harmonize the various fire testing procedures that existed throughout the European Union. Euroclass has now been adopted by the member countries and after a transitional period is now replacing existing nation testing certification.

Since this common standard for building materials is now implemented it basically means that all building materials that are manufactured and sold in the EU are subject to the Euroclass system. This in turn identifies their fire preventive properties and helps indicate their suitability for building application.

In Poland, until the moment of complete introduction of the Euroclass system (predicted for the year 2011), both the current and Euroclass system will exist.

The system is divided into various classes in accordance to the following:

| A1 | Non-flammable | No contribution to fire |

| A2 | Non-flammable | No noticeable contribution to fire |

| B1 | Flammable | None or small contribution to fire |

| C | Flammable | Limitted contribution to fire |

| D | Flammable | Contribution to fire |

| E | Flammable | Major contribution to fire |

| F | Flammable | Not classified within classes A1-E |

The European norm introduces new additional classes:

| Smoke production | s1 | s2 | s3 |

|

Flamming droplets / particle class |

d0 | d1 | d2 |

The best smoke class is: s1,

The best droplet / particle class: d0

GUSTAFS PANEL SYSTEM® IS CLASSIFIED ACCORDING TO EUROCLASS AS: B-s1, d0

IN POLAND CLASSIFIED AS: Non-ignitable

The newest tests and researches results, regarding Gustafs Panel System®, are available on www.gustafs.com